- Digital Transformation in Supply Chain Management: Key Market Insights and Trends

- Traditional Vs Digital Supply Chains

- Why Does Digital Transformation Matter In Supply Chain Management?

- Organizational Flexibility

- Better Decision Making

- Increased Automation

- Accelerated Innovation

- End-to-End Customer Engagement

- Better Business Outcomes

- Real-Time Tracking and Visibility

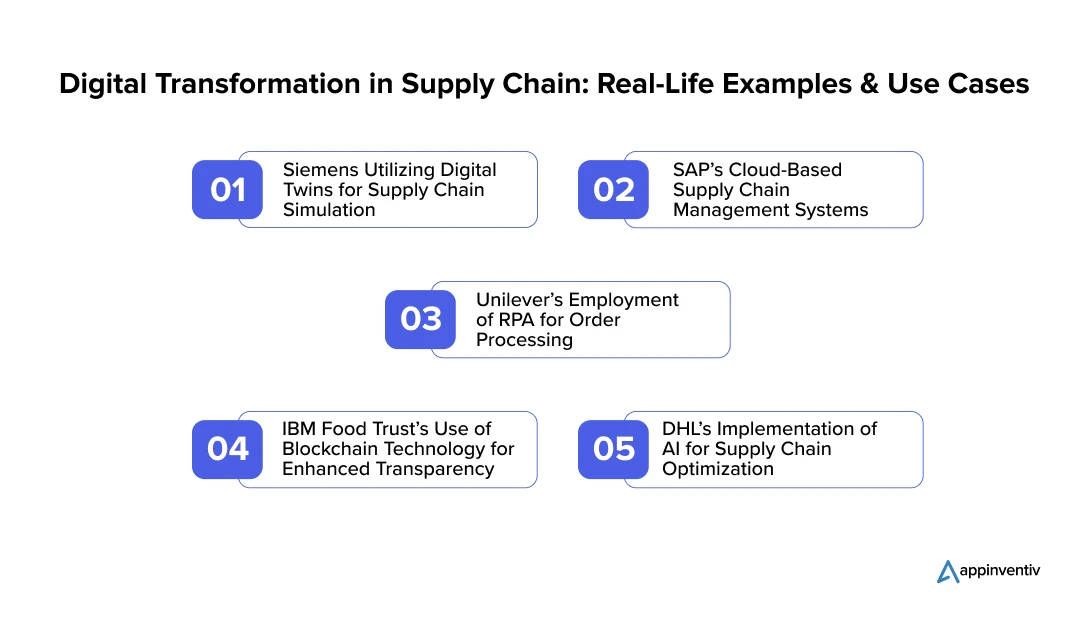

- Real-Life Examples of Digital Transformation in Supply Chain

- Siemens Utilizing Digital Twins for Supply Chain Simulation

- SAP’s Cloud-Based Supply Chain Management Systems

- Unilever’s Employment of RPA for Order Processing

- IBM Food Trust’s Use of Blockchain Technology for Enhanced Transparency

- DHL’s Implementation of AI for Supply Chain Optimization

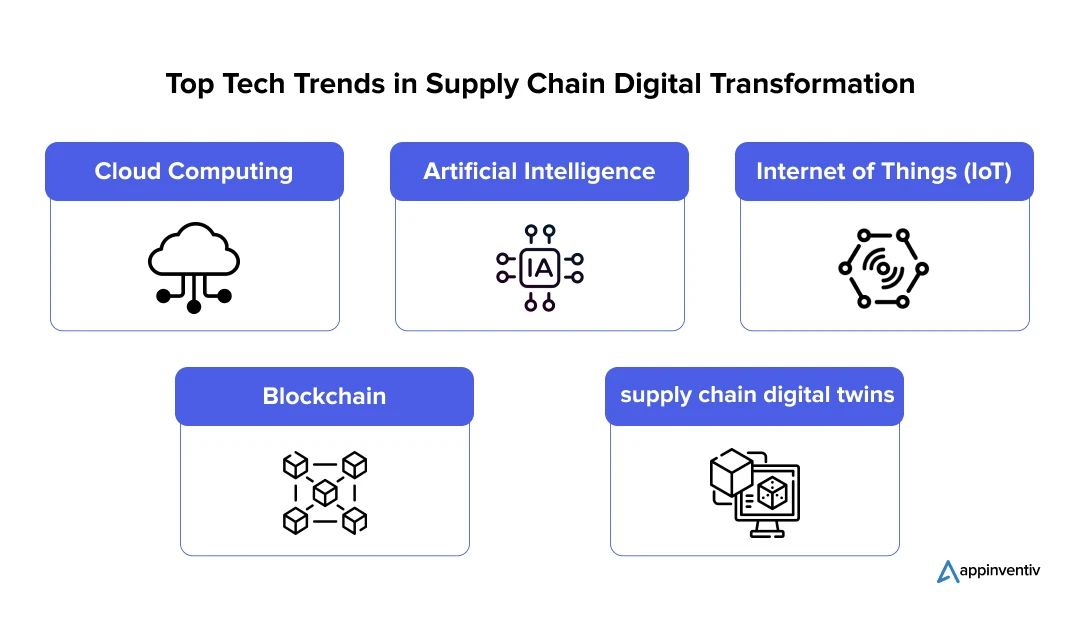

- Top Tech Trends in Supply Chain Digital Transformation

- Cloud Computing

- Artificial Intelligence

- Internet of Things (IoT)

- Blockchain

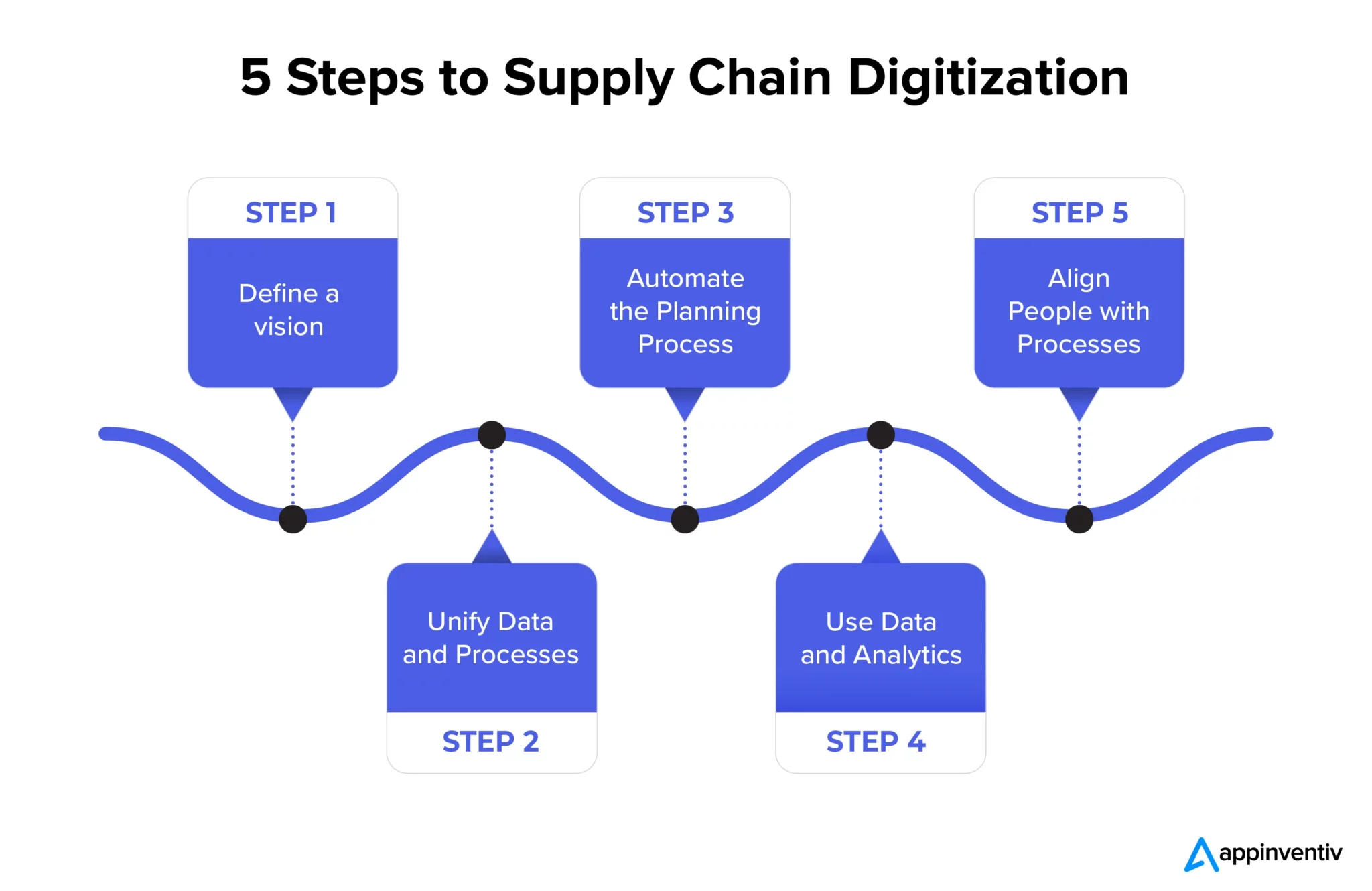

- Five Steps to Digitizing Supply Chain

- Define a Vision

- Unify Data and Processes

- Automate the Planning Process

- Use Data and Analytics

- Align People with Processes

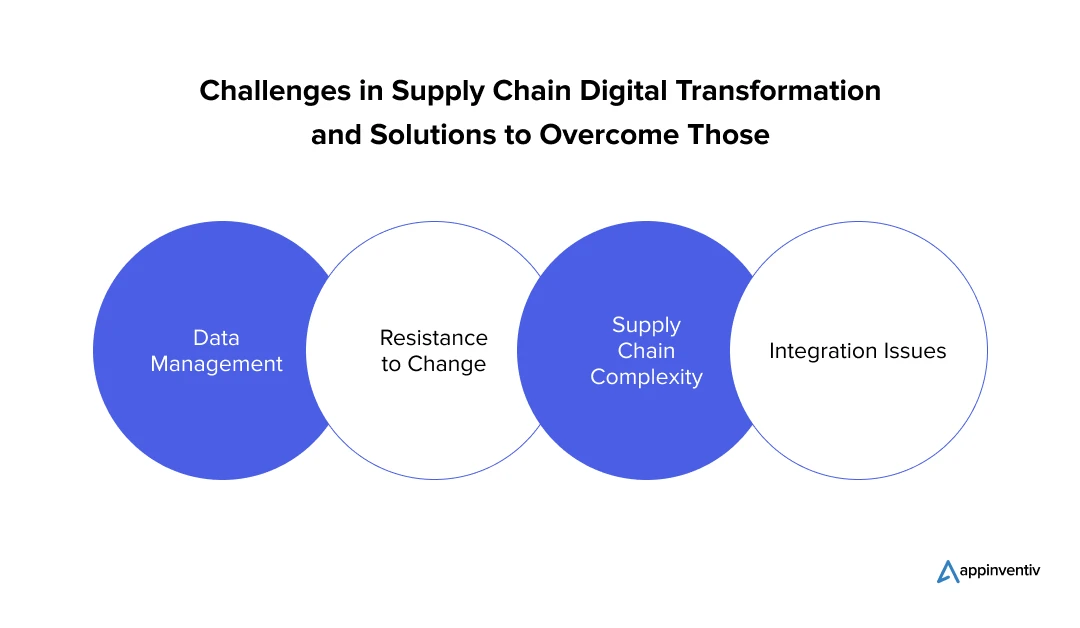

- Overcoming Challenges in Supply Chain Digital Transformation

- Data Management

- Resistance to Change

- Supply Chain Complexity

- Integration Issues

- How Can Appinventiv Help You Bring Supply Chain Digital Transformation into the New Reality?

- FAQs

In an era marked by supply chain disruptions, economic uncertainty, and stringent new regulations, the role of digital transformation in supply chain management has become more critical than ever. The amalgamation of supply chain and digital transformation are increasingly critical as they together navigate challenges such as product shortages and economic volatility.

The traditional approach of merely monitoring direct suppliers and customers is no longer sufficient. To stay competitive and responsive, businesses must adopt a comprehensive, real-time view that spans beyond immediate partners, encompassing the entire network of suppliers and customers.

Digital transformation supply chain management provides the tools necessary to achieve this extended visibility, offering advanced analytics and integration capabilities that enable proactive management and strategic agility. Embracing these technologies ensures that your supply chain can effectively address current challenges and capitalize on emerging opportunities, thereby driving long-term success and resilience.

Digital Transformation in Supply Chain Management: Key Market Insights and Trends

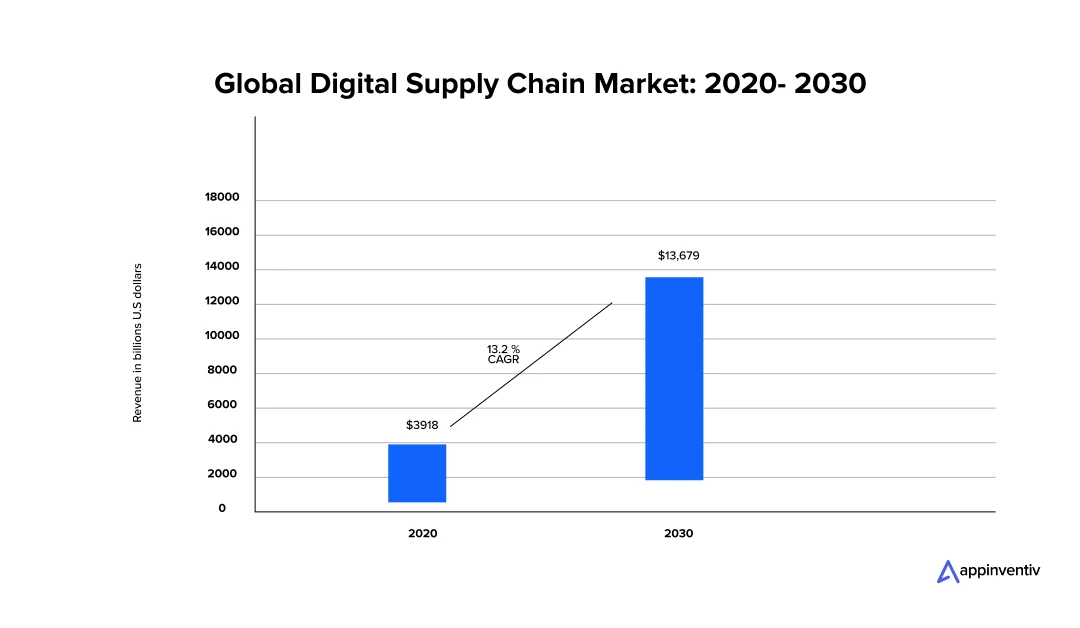

In the past few years, there has been a gradual adoption of supply chain management digital transformation, reflecting its increasing importance in enhancing operational efficiency and agility.

As per a report by Allied Market Research, the global digital supply chain market is expected to reach a valuation of $13,679 million by 2030, growing at a CAGR of 13.2%. The market growth is fueled by factors such as advancements in technology, rising demand for real-time data and analytics, the need for greater supply chain transparency, and the growing emphasis on sustainability and risk management.

Additionally, the expansion of eCommerce and the necessity for more agile responses to consumer expectations are driving businesses to invest in digital supply chain solutions, further accelerating market development.

According to a KPMG survey, 50% of supply chain organizations plan to invest in AI and advanced analytics applications. Additionally, research from MIT’s Center for Transportation and Logistics reveals that digital transformation in the supply chain can reduce process costs by up to 50% and boost revenue by 20%.

Therefore, there’s no denying that organizations that are willing to digitize their supply chain management can improve agility, efficiency, and visibility by leaps. On that note, let’s dive into how digital supply chain management differs from a traditional supply chain.

Traditional Vs Digital Supply Chains

Traditional supply chains function on rules based on historical transactional inputs, while supply chains integrated with digital technologies function in real-time. While digital supply chains are networks, traditional supply chains are linear.

In digital supply chain management, information from IT and operational technology systems are integrated, while traditional supply chains often rely on standalone systems. Traditional supply chains require a lot of legwork when it comes to spotting possible problems and predicting likely risks.

In contrast, with supply chain digital transformation, shared quality and control data can enable companies to anticipate issues and take immediate precautionary measures. Above all, in digital supply chains, machines drive the decisions with human oversight, while in traditional supply chains, humans make decisions based on machine inputs.

To better understand the differentiation, check out this detailed table below:

| Aspect | Traditional Supply Chain | Digital Supply Chain |

|---|---|---|

| Operation | Relies on historical data and past transactions for process management. | Functions in real-time, using current data to make immediate decisions. |

| Structure | Follows a linear path from suppliers to consumers with a series of sequential steps. | Employs a networked model with interconnected systems and multiple points. |

| System Integration | Often operates with separate, standalone systems that have limited interconnectivity. | Features integrated IT and operational technology systems for smooth data exchange. |

| Problem Detection | Depends on manual efforts to spot issues and forecast potential risks. | Uses integrated data to predict problems and take preventive actions proactively. |

| Decision-Making | Decisions are mainly made by humans based on information from various machines and reports. | Driven by automated systems and algorithms, with human oversight for final decisions and strategic adjustments. |

Why Does Digital Transformation Matter In Supply Chain Management?

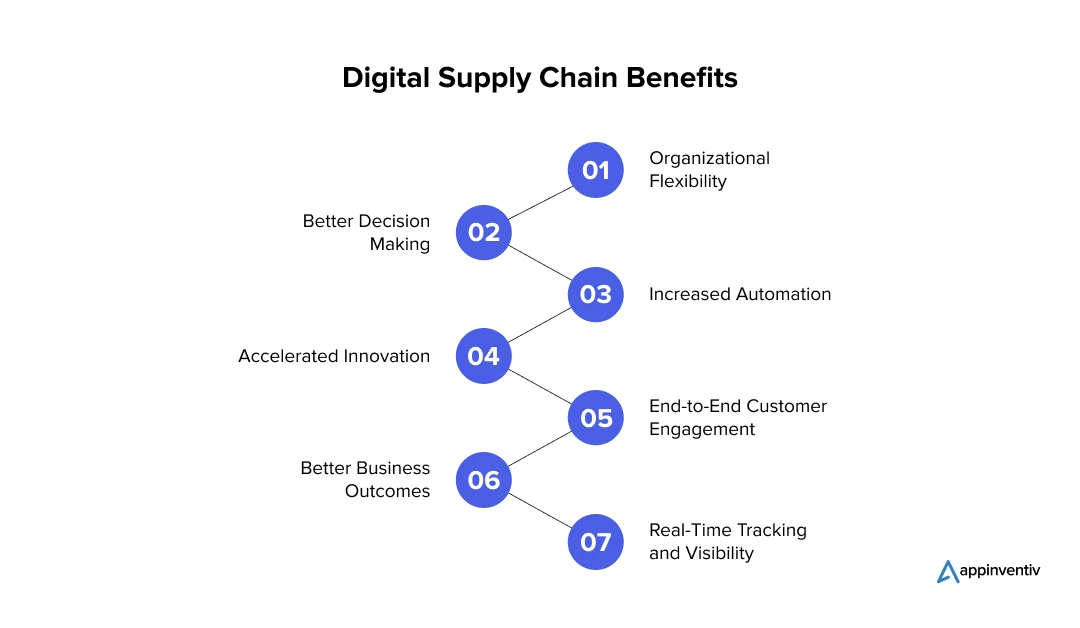

Digitization in supply chain management empowers your planning, sourcing, and logistics teams to collaborate, automate, and effectively leverage analytics. It has also proven to drive growth, mitigate risk, and optimize costs.

Here are a few supply chain digital transformation benefits explained in detail, so let’s dive in!

Organizational Flexibility

With a digital operating model, management has greater freedom to choose the appropriate degree of centralization needed to support specialization or minimize process costs, given different local labor costs and productivity levels across locations. A significant benefit for an organization when it centralizes certain specific functions is higher value through better quality and productivity.

Better Decision Making

Digital transformation for the supply chain helps businesses make faster and more informed decisions for every specific operation. Also, you can measure performance accurately and efficiently by aggregating transactions and available information at the macro level, making appropriate decisions to avoid distortions from average costing.

For instance, BASF, a German multinational chemical corporation, uses AI and machine learning-based technologies to accurately predict when the product stock is running low and the optimal time to replenish supply and minimize disruptions. This has led to increased visibility into inventory levels, which supports smarter replenishment planning, more efficient decision-making, and, ultimately, better customer service.

The recent tech development in digital twin technology for businesses has also brought a model-driven decision-making approach into the picture for sustainability and feasibility.

Increased Automation

An end-to-end digital platform creates efficiency, improves data accuracy, and increases supply chain efficiency by automating many labor-intensive processes and facilitating decision-making at multiple stages in the lifecycle. Digital transformation supply chain management also determines the most appropriate shipping mode, carrier, and schedule while considering time, speed, priority, and other elements.

For instance, alerts are generated automatically when purchase orders are at risk of delays or complications. This helps companies take precautionary measures and be better prepared to handle customers.

Accelerated Innovation

Your supply chain digital transformation goals must be to drive innovation and optimize efficiency. Transitioning from traditional supply chain methods to advanced digital solutions can significantly enhance operational capabilities. This evolution not only strengthens the company’s business model but also builds more strategic and collaborative relationships with suppliers and customers.

By focusing on digital transformation in supply chain goals, organizations can streamline processes, foster innovation, and maintain agility, allowing them to adapt swiftly to market changes and sustain long-term growth.

Embracing digital technologies enables companies to develop new products, optimize processes, and respond swiftly to market changes. The result is a more agile, forward-thinking organization that can adapt to evolving industry trends and drive sustainable growth.

End-to-End Customer Engagement

Supply chain management digital transformation helps increase customer engagement. For example, after placing an order, a customer will stay updated with his order details until receiving it with the help of the supplier’s automated tracking system. This will ensure that customers have more control, feel more secure, and appreciate their experience when buying that brand.

Farmer Connect is a company that uses technologies like Blockchain to connect coffee growers with the consumers they serve. They have launched a mobile application, ‘Thank My Farmer,’ that allows coffee lovers to trace the quality and origin of their coffee and even support the farmer who grew the beans. The app connects the user to farmers, traders, roasters, and brands.

Better Business Outcomes

Digital supply chain transformation drives better business outcomes by enhancing performance, agility, and resilience. Advanced technologies accelerate operations and enable real-time data insights, which help organizations swiftly adapt to changes and mitigate risks.

By leveraging strategic and emerging technologies, businesses can optimize their supply chain processes, improve decision-making, and achieve greater efficiency across the broader ecosystem.

Real-Time Tracking and Visibility

Real-time tracking technologies, including IoT sensors and GPS, allow companies to continuously monitor the location and status of shipments and inventory. This enhances visibility, enables swift responses to delays, and improves overall supply chain efficiency.

Walmart employs IoT and GPS technologies to achieve real-time tracking of its supply chain, greatly enhancing operational transparency and efficiency. These technologies enable Walmart to oversee inventory levels and track shipment progress, quickly address any issues, and ensure timely delivery throughout its extensive network.

Real-Life Examples of Digital Transformation in Supply Chain

By implementing digital transformation in logistics and supply chains, businesses can achieve enhanced operational efficiency, greater visibility, and improved responsiveness. However, it also offers a series of other digital supply chain transformation benefits as visible through these real examples.

Siemens Utilizing Digital Twins for Supply Chain Simulation

Digital twins create virtual replicas of physical assets or processes, allowing for the simulation and optimization of supply chain operations before making real-world changes. This approach enhances decision-making and operational efficiency.

Siemens utilizes digital twin technology to develop virtual models of their supply chain processes, enabling simulation and optimization in a controlled environment. This technology helps Siemens improve operational efficiency by testing and refining processes virtually before applying them in the real world.

SAP’s Cloud-Based Supply Chain Management Systems

Cloud-based systems offer real-time visibility, collaborative planning, and advanced analytics for managing logistics and supply chain operations. They facilitate improved coordination and data sharing across the supply chain.

SAP Integrated Business Planning (IBP) provides cloud-based solutions designed to enhance real-time visibility and facilitate collaborative planning. By leveraging these tools, organizations can streamline supply chain activities, optimize inventory management, and boost overall efficiency, ensuring seamless integration and improved operational performance.

Unilever’s Employment of RPA for Order Processing

RPA automates repetitive and rule-based tasks such as data entry and order processing. This technology minimizes manual errors, accelerates workflow efficiency, and allows employees to focus on more complex and strategic responsibilities.

Unilever employs RPA to enhance its supply chain operations by automating order processing and inventory management tasks. By integrating RPA, Unilever improves operational efficiency, reduces errors, and streamlines supply chain activities, enabling teams to concentrate on strategic planning and overall supply chain optimization.

IBM Food Trust’s Use of Blockchain Technology for Enhanced Transparency

In supply chain optimization processes, Blockchain technology guarantees traceability and authenticity by documenting every stage of the supply chain on an immutable ledger. It offers a secure, transparent ledger for recording transactions and data.

IBM’s Food Trust platform utilizes blockchain to enhance transparency and traceability throughout the food supply chain. By recording each step of the journey from farm to table on a secure, immutable ledger, IBM Food Trust helps ensure product authenticity, reduce fraud, and increase consumer confidence in the food supply chain. This technology also enables quick identification and resolution of issues, such as food recalls.

DHL’s Implementation of AI for Supply Chain Optimization

AI-driven supply chain optimization uses sophisticated algorithms to boost logistics efficiency by forecasting delivery times, streamlining route planning, and managing potential disruptions. This technology enhances decision-making and operational effectiveness.

DHL employs AI and machine learning to optimize its supply chain and logistics processes. By analyzing extensive data, DHL’s AI systems accurately predict delivery times, refine route planning to cut fuel costs, and proactively manage disruptions, leading to substantial cost reductions and improved efficiency.

Top Tech Trends in Supply Chain Digital Transformation

Let’s get started with the different digital supply chain technologies and trends you must optimize in 2024 and beyond to enhance your organization’s overall productivity and performance.

Cloud Computing

The ever-rising demand for cloud computing is also an emerging tech practice that has helped accelerate supply chain digitization. Now, companies store data on local servers instead of storing it on the cloud for easier and faster accessibility. In the long term, with cloud computing adoption in logistics and supply chain, companies can easily access the needed information and share it with other companies or stakeholders anywhere, anytime.

Artificial Intelligence

Artificial intelligence (AI) in the supply chain consists of a toolbox of technology options that help companies understand complex content, enhance human performance, and take over routine tasks.

AI and analytics help supply chain leaders solve long-standing data silos and governance challenges. Its capabilities allow for more integration and visibility across networks of previously remote or disparate stakeholders.

Internet of Things (IoT)

IoT is a network of physical objects connected to the Internet. It already plays a significant role in the supply chain, but it will likely continue to grow in importance with increasingly diverse applications.

Also, utilization of IoT in manufacturing and supply chains can also improve warehouse management, fleet tracking, inventory control, and even technological and mechanical maintenance. It could even be used to create entirely smart warehouses and fleets, increasing efficiency.

Blockchain

Blockchain technology is revolutionizing supply chain management by enhancing transparency, security, and efficiency. It creates a decentralized, immutable ledger that connects various stakeholders, such as carriers, shipping lines, and logistics providers, on a single platform.

This integration minimizes disruptions and reduces inefficiencies by providing a clear and tamper-proof record of transactions. Additionally, blockchain’s real-time data processing capabilities enable businesses to detect and address potential issues before they escalate, thereby improving overall customer service and operational reliability.

Five Steps to Digitizing Supply Chain

Moving from a traditional supply chain to a digital one is a complex process, but taking the first step is essential if you want to reap the maximum benefits of digitalization in supply chain management and logistics. Here are the steps that will help you prepare for digital transformation in supply chain management.

Define a Vision

The first step for implementing supply chain management digital transformation is to define a clear vision. Make sure that the vision is aligned with your enterprise goals. These goals can be related to your business objectives, such as better and faster decision-making, automated operations, and improved supply chain visibility.

- Assess resources and existing systems: Identify what capabilities you’ll need to achieve your transformation goals and determine the gaps.

- Legacy systems: Ensure that your existing systems use technology to support your new goals. Is the technology used by you aligned with your business objectives? Identify digital solutions and legacy systems to help achieve the desired business outcomes.

- Data collection and analysis: Assess the capabilities of existing systems to generate, collect and analyze data. Check if the data can be accessed easily to draw actionable insights.

- Workforce skills: Determine if your team has the required skills to work with and adapt to the new business model.

Unify Data and Processes

Develop a unified platform to gain complete, end-to-end supply chain visibility. Utilize enhanced transparency for streamlining core functions, including smart inventory management, warehouse management, demand forecasting, and logistics. The main objective is to increase visibility for every role and process across the extended supply chain.

Also Read- How much does it cost to build a DAM software like Brandfolder

Automate the Planning Process

With automated planning, you can simplify tasks and derive meaning from large volumes of data. Replace routine or recurring tasks with automated processes. But do not automate processes that involve complex situations or require collaboration between planners.

Use Data and Analytics

Supply chain leaders need access to real-time data to make informed decisions. This data also helps them effectively deal with partners, suppliers, and related functions, identify potential disruptions, and increase visibility across the supply chain.

Moreover, AI-powered analytical tools can improve planning processes and yield actionable insights. For instance, analytics can help prevent an out-of-stock situation and adjust inventory accordingly.

Align People with Processes

Even if you shift to a digital supply chain, it would be futile if your team members were not aligned with the new techniques and processes.

This shift should integrate technologies with processes, people, and management. Without such integration, teams may not be able to achieve the desired results in the new business model.

[Also Read: Understanding Load Planning Software Features and Cost]

Overcoming Challenges in Supply Chain Digital Transformation

Effective digital transformation in supply chains requires a strategic approach to overcome various hurdles. By implementing well-designed solutions and leveraging advanced technologies, organizations can streamline processes, enhance data management, and ensure smooth integration with existing systems.

Let’s take a detailed look at supply chain digital transformation challenges and their potential solutions.

Data Management

Handling and ensuring the quality of large volumes of data across the supply chain can be challenging, leading to inconsistencies and errors. This complexity often results in fragmented information and reduced data reliability, impacting overall decision-making and operational efficiency.

Solution: Set up robust data governance practices to ensure accuracy, consistency, and security across all data sources. Implement data quality management processes and leverage advanced analytics tools to streamline data integration, manage data effectively, and extract valuable insights. This approach will help ensure that data-driven decisions are based on reliable and comprehensive information.

Resistance to Change

Employees and stakeholders might resist adopting new digital tools due to concerns about job security or disruptions to familiar workflows, potentially hindering the transformation effort.

Solution: Develop a strong change management plan that includes clear communication about the benefits, comprehensive training, and early employee involvement to address their concerns and illustrate how the new technologies will improve their work.

Supply Chain Complexity

Variations in system capabilities, data formats, and operational practices among different partners add layers of complexity, making the seamless integration of digital transformation in the supply chain a challenging endeavor. This can lead to inefficiencies, delays, and difficulties in achieving a unified vision for transformation.

Solution: Adopt industry standards and best practices to streamline processes and enhance interoperability. Utilize collaborative platforms to improve communication and coordination among all supply chain partners, ensuring that all parties are aligned and working towards common goals.

Integration Issues

Merging new digital solutions with existing legacy systems can be complex and expensive, leading to potential disruptions. Legacy systems often use outdated technologies and data formats, which may not be compatible with modern solutions, complicating the integration process.

Solution: Implement a step-by-step approach, allowing for gradual integration and minimizing disruption. Employ middleware or integration platforms to bridge the gap between legacy systems and new technologies, ensuring smooth data flow and compatibility. This approach helps manage risks and ensures that integration is both efficient and effective.

What’s Next?

For businesses re-evaluating their supply chains, now is the best time to start implementing their plans. Supply chain management digital transformation today is one of the most effective and safest ways to build a resilient business.

If you face any challenges in your digital transformation journey, you can partner with a trusted company (like Appinventiv) to take care of your adoption and migration needs.

How Can Appinventiv Help You Bring Supply Chain Digital Transformation into the New Reality?

As a trusted partner in digital transformation consulting services, we are ready to help you familiarize yourself with changes through the shortest learnability curve. We have helped many companies worldwide digitally transform their business operations.

At Appinventiv, we focus on value. Our proficient team uses various technologies and methodologies to digitize your supply chain. We develop a tailored roadmap for digital transformation in supply chain management, simplifying the process of enhancing and modernizing your operations. This approach ensures you can effectively realize the benefits of upgrading your supply chain processes and operations.

We first map the critical activities and conduct scenario analysis to figure out the feasible areas for disruption, then develop future contingency plans that build resilience.

Drawing on a wealth of experience and expertise, Appinventiv specialists leverage new technologies to ensure our systems are secure, agile, robust, and scalable. As a leading supply chain management services provider, we have developed a series of technology accelerators and proprietary operating software that can turbo-charge your business and make digital supply chain transformation a reality.

We also have an extensive portfolio of working top brands like Pizza Hut, IKEA, and Adidas, helping them digitally transform and make greater customer engagement with higher returns.

Partner with us now. The world of supply chain digitization awaits you!

FAQs

Q. What is digital transformation in supply chain?

A. The quickly changing technological landscape and heightened customer expectations are causing organizations to revisit how they do business. This is where supply chain digitization comes in. Integrating the supply chain with digital technologies can lead to greater efficiency, flexibility, and building resilience.

Simply said, supply chain digital transformation is integrating and utilizing top tech trends into all areas of a business, essentially modifying how companies operate and deliver value to customers. Also, digital supply chain management is not just about technological change; it’s also a cultural change that helps companies to upgrade their status quo, experiment, and learn from failure.

Q. How has digital technology impacted the supply chain?

A. The changing scenario and the demand of machine customers make the CSCOs look for various ways to optimize activities and build on capabilities in different aspects of the supply chain. So, adopting the following technologies in the supply chain transformation process is essential to revolutionize supply chain models and fit well with the needs of today’s companies.

- More integration

- Blockchain

- AI, AR/VR

- Eco-friendliness

- Circular supply chain

- Elastic logistics

Q. Why is digital transformation of the supply chain important?

A. Analyzing the ever-growing demand of machine customers and the pressing need for digital solutions to fulfill those demands, we can see that digital transformation in the supply chain is inevitable. It helps companies gain a competitive edge over technological advancements, leaving their rivals far behind.

Moreover, the future of the corporate world lies in the successful adoption and utilization of blockchain, IoT, deep data analytics, and other SCM innovations. Thereby, businesses in the supply chain must delve deep into digital transformation without hesitation.

Q. How to plan supply chain digital transformation?

A. To plan digital supply chain transformation, begin by evaluating existing processes and setting clear objectives. Develop a detailed strategy, choosing relevant digital technologies like AI or blockchain, and define how they will be integrated. Execute the transformation in stages to minimize risks and regularly review progress to refine strategies for the best outcomes.

To know more about how to prepare to digitally transform your supply chain, connect with our experts today!

How Digital Transformation is Shaping the Next Era of Construction

The construction industry, traditionally slow to adopt new technology, is now actively embracing digital transformation, marking a significant shift towards modernization and increased productivity. This change is all about adopting new solutions that enhance efficiency, safety, and project management, offering significant benefits to businesses. While the complexity of construction projects and coordination among multiple parties…

How Digital Twins Act as Key to Smarter and More Agile Manufacturing Processes - 10 Use Cases and Examples

Tapping into the potential of digital twins in manufacturing, businesses today are creating a transformative virtual, real-time counterpart of physical systems, making it easier to monitor, assess, and optimize their manufacturing operations. McKinsey highlights the value of this approach, pointing out how “a company with a robust digital-twin platform can conduct comprehensive full-product simulations in…