- The Role of AI in Revolutionizing the Global Food Market

- Game-Changing Artificial Intelligence Applications in the Food Industry

- Agriculture

- Food Manufacturing

- Food Packaging

- Cooking

- Food Delivery

- Supply Chain Administration

- Creation of New Products

- Food Sorting Options

- Food Retail

- Advantages of Implementing AI in Food Robotics Automation

- Enhanced Precision and Consistency

- Increased Efficiency

- Cost Reduction

- Improved Safety and Hygiene

- Flexibility and Scalability

- Enhanced Customer Experience

- Data-Driven Decision Making

- Waste Reduction and Sustainability

- Real World Examples of Businesses Using AI in the Food Industry

- Coca-Cola

- Starbucks

- Beyond Meat

- Nestlé

- Revolutionizing the Food Industry: The Future of AI and Robotics

- Overcoming Challenges and Implementing Solutions for AI and Robotics in Food Automation

- Unlock Opportunities in Your Food Business with Appinventiv’s Intelligent AI Services

- FAQs

AI in the Food Industry – How Artificial Intelligence and Robotics Are Transforming the Sector

Technology is typically the first thing that comes to mind when discussing the setbacks of the modern food industry and the strategies to overcome them. In today’s tech-driven age, the integration of AI in fast food industry is indispensable to streamline day-to-day operations, address industry challenges, and eventually transform business in a major way!

The automation of the food industry has revolutionized how we produce, store, serve, deliver, and consume food. AI technologies like machine learning, data analytics, Generative AI, and computer vision are transforming traditional agricultural practices, optimizing supply chain logistics, reducing waste, predicting consumer demands, and enhancing food safety standards.

Unsurprisingly, the technology is redefining almost every aspect of the food ecosystem, from precision farming and crop yield prediction to personalized nutrition and smart food delivery systems.

As AI continues to expand its wings in the smart agriculture and modern food industry, including the beverages section, the technology can further impact the efficiency and sustainability of the food ecosystem in multiple ways. All for the good.

Let’s explore the profound impact of AI in the food industry, highlighting its benefits, applications and potential to address global challenges and cater to the rapidly evolving demands of today’s consumers.

We will also delve into the exciting world of AI, robotics, drones, and 3D printing in the food industry, exploring the endless possibilities and advancements that await. Let’s check them out.

The Role of AI in Revolutionizing the Global Food Market

The food industry has undergone a significant transformation in recent years due to the widespread adoption of AI and robotics. For instance, machine learning algorithms in food production increase accuracy and efficiency, enabling food businesses to reduce waste, make well-informed choices and quickly adapt to shifting market trends.

Furthermore, robotics automate repetitive processes, such as packing, sorting, and processing, helping food businesses enhance presentation and save operating costs.

With AI and ML taking care of routine tasks and driving innovation, human resources can dedicate their energy to providing services and engaging in tasks that require their unique cognitive abilities. This not only increases productivity and drives efficiency but also allows organizations to improve customer experience and gain competitive advantages.

According to Statista, the global food automation and robotics market is anticipated to grow by around 5.4 billion units by 2030. This proves that the future of the food sector will be shaped by the seamless integration of AI and robots, which is positioned to spur innovation, efficiency, and sustainability.

(Also Read: AI, AR, and VR: The Three Elements that are Making Food Technical)

Game-Changing Artificial Intelligence Applications in the Food Industry

The food business is transforming rapidly to meet the expanding demands of a growing population. Suppliers are under increasing pressure to provide higher-quality, sustainable food while enhancing efficiency.

Automation and robotics are playing a crucial role in this digital transformation. The integration of AI & ML into the food industry ensures a more resilient and sophisticated food ecosystem by promising better productivity and responsiveness to market needs.

Let’s delve deeper to understand how AI applications in food industry are providing innumerable opportunities:

Agriculture

AI and robotics are transforming agriculture, improving production, sustainability, and efficiency. For instance, precision agriculture, led by AI-powered drones and robots with cutting-edge sensors, can monitor crops, soil conditions, and water use.

Machine learning algorithms examine data to determine the best times to plant, forecast yields, and identify diseases early, improving agricultural management and decreasing waste. Furthermore, AI-driven automated farm equipment efficiently performs rule-based tasks like planting, harvesting, and weeding with minimal human intervention.

Also Read: HMI Software Development – Benefits, Process, Features, Costs and More

Food Manufacturing

Autonomous food manufacturing is the key to tackling the rising food demand. This process entails a variety of stages, such as packing and safety training, that are usually performed in a production facility.

Robots can clean and categorize different sorts of food. For example, robotic systems can sort fruits and vegetables in different containers. Additionally, some foods can be processed by robots before packaging. Since various cutting tools are needed to slice fruits and vegetables, robots can operate more effectively by matching blades to the chop that is needed. These robots can also be used independently in the supermarket for cutting and cooking.

Food Packaging

After manufacturing, robotics and artificial intelligence in food processing can assemble the components of a packaged meal, such as frozen meals. Additionally, these robotic systems can organize food in boxes for storage and shipment, streamlining, simplifying, and even speeding up store operations.

AI-powered quality control ensures each meal meets stringent standards, while predictive maintenance keeps the machinery running smoothly. These advancements not only enhance efficiency but also reduce food waste and improve overall product quality.

Cooking

Restaurants have already embraced AI and robotics to prepare scrumptious food. This cutting-edge technology can handle various tasks, from chopping and roasting to garnishing and serving the final dish.

The demand for robotic cooks is on the rise, whether in small kitchens or large facilities. Robots are taking over laborious prep tasks and replacing human staff, leading to increased efficiency and consistency in food preparation.

These machines might soon start to appear in home kitchens as well, bringing advanced cooking capabilities to everyday households. However, robotic cooking and delivery are still in their infancy, and wider adoption is necessary to transform the global food supply. As technology advances and becomes more accessible, we can expect significant changes in how food is prepared and delivered on a global scale.

Food Delivery

Despite appearing to be “simply the newest craze,” automated food delivery attempts to address growing industry trends through AI food industry solutions. A significant increase in demand for ready-to-eat food items has been observed in recent years. It’s debatable whether autonomous delivery will catch on, but there’s no denying that our passion for ordering food is revolutionizing the food industry.

Also, stakeholders in the food industry have been testing the options of delivering food with the help of drones. There, of course, are some challenges that are being worked upon. However, the adoption of such automation will bring a remarkable impact on the delivery process.

How Appinventiv Helped KFC Build a Pioneering Food Delivery App

KFC partnered with us to create a food delivery app that enabled users to track their order delivery’s real-time status, expanding its digital presence in the global arena. With 2 million downloads and a 28% conversion rate, the app was ranked number one on Play Store.

In order to make more customers order from the KFC food delivery app instead of aggregator apps, it was essential to boost the customer experience. To achieve this, our experts implemented top-notch AI-based personalization features that made it easier for the customers to keep track of their order history, place order in accordance with special offers and pizza category choices, and make hassle-free payments through multiple gateways.

(Also Read: How much does it cost to develop an app like KFC?)

Supply Chain Administration

Supply chain management is a significant responsibility for all food businesses due to new rules around food standards and the increasing demands for disclosure. The use of generative AI in food industry enhances supply chain operations by:

- Food standards surveillance

- Product testing at each level

- Managing inventories with accurate estimates

- Tracking of products from harvest to distribution

- Ensuring that staff adheres to basic hygiene standards

Food Safety Compliance

To ensure food safety compliance, maintaining strict hygiene practices in food plants is crucial. Advanced methods involve using cameras with facial and object recognition software for real-time employee monitoring, ensuring they follow safety protocols. AI-powered systems can generate automated compliance reports and predict equipment malfunctions by scheduling timely maintenance. For employee training, AI provides instant feedback on hygiene practices.

Additionally, AI-driven traceability systems enhance accountability by tracking the entire food production process. Integrating these AI technologies helps manufacturing facilities and restaurants improve hygiene and food quality standards, ensuring top-notch safety compliance and consumer satisfaction.

Creation of New Products

One of the main benefits of AI in the food industry is that it assists food manufacturers in creating new products. It can apply algorithms to identify trends in the food sector and predict their growth. The technology predicts consumer tastes, patterns, and forecasts how consumers will react to new foods using machine learning and artificial intelligence analytics. To assist businesses in creating new items that suit the interests of their target market, the data can be split into geographical categories.

This strategic approach enables them to effectively control the market and solidify their position as industry leaders.

Food Sorting Options

Food sorting is greatly aided by AI and robotics because they have enhanced automation and intelligence. AI systems examine photos and sensor data to precisely identify flaws, sizes, and quality of food items. Precision actuator-equipped robotics sort and separate the products based on predetermined parameters.

With less human error and lower labor expenses, this combination assures quick and reliable sorting. With AI technology, food manufacturers can uphold quality standards, cut waste, and improve the effectiveness of their supply chains, ultimately giving customers access to fresher and safer goods. Furthermore, AI-driven analytics offer insightful data that supports process optimization and ongoing development.

Food Retail

AI is widening the horizon of how food retailers operate by optimizing inventory management, predicting demand based on historical data, seasonal trends, and real-time analytics to reduce waste and ensure shelves are stocked with what you need.

Personalized shopping experiences are enhanced through AI-driven recommendations, which analyze your purchase history and preferences to suggest items you might like. Dynamic pricing strategies leverage AI to adjust prices in real-time, considering market conditions and competitor pricing to stay competitive and maximize profits.

These 10 areas of AI in the food and beverage industry demonstrate how the technology has the potential to create change. AI and robotics are essential for taking this sector to the next level because of their usefulness, reliability, and client experience.

If you are still confused regarding the innumerable benefits of AI in the food industry, have a look at a few of the most important ones listed below.

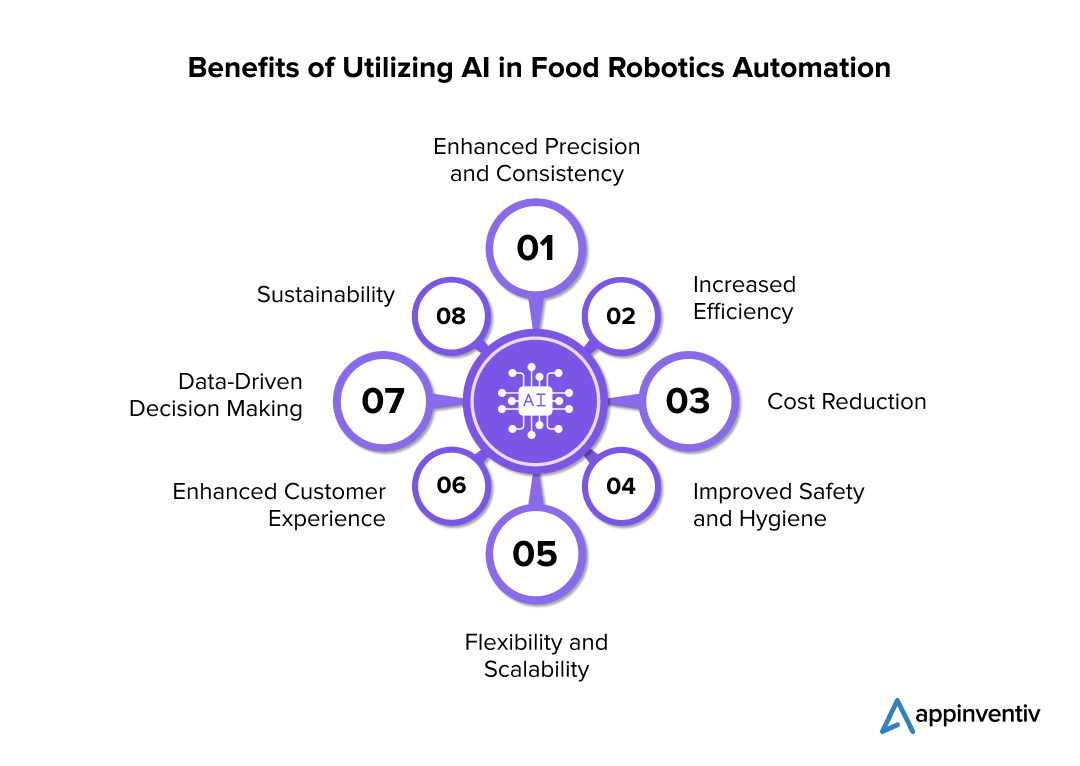

Advantages of Implementing AI in Food Robotics Automation

Implementing AI in the food service industry demonstrates numerous opportunities by enhancing precision, efficiency, and safety. These advancements lead to cost savings, improved customer experiences, and sustainable practices. Let’s comprehend in detail!

Enhanced Precision and Consistency

AI in the food service industry can perform repetitive tasks with high precision, ensuring consistent quality and reducing human error. This is crucial in food preparation, as even minor deviations can affect taste and safety. Additionally, AI systems can monitor and adjust recipes in real-time, ensuring that every dish meets the same high standards. This not only improves the dining experience but also builds customer trust and loyalty.

Increased Efficiency

AI technology in the food industry can work continuously without breaks, significantly increasing productivity. They can handle tasks faster than human workers, leading to quicker turnaround times and improved operational efficiency. Moreover, AI systems can be integrated with inventory management and supply chain logistics to streamline operations and minimize downtime, further boosting overall efficiency.

Cost Reduction

Investing in AI and robotics isn’t just a technological upgrade; it’s a strategic move toward substantial long-term savings. These advanced technologies dramatically cut labor costs by automating repetitive tasks, while precision and efficiency minimize waste and reduce error rates.

Moreover, AI-powered predictive maintenance anticipates and prevents equipment failures, reducing downtime and associated repair costs. This proactive approach ensures smoother, more cost-effective operations, enabling businesses to reinvest their savings into growth and innovation.

Improved Safety and Hygiene

Robots are capable of functioning in environments hazardous to human health, such as areas with extreme temperatures or exposure to toxic chemicals. In the food service industry, AI-driven systems ensure exceptional hygiene standards, critical for food handling and preparation.

By automating tasks that require direct food contact, AI significantly reduces the risk of contamination and enhances compliance with stringent health and safety regulations. This not only protects workers but also assures consumers of the highest safety and cleanliness standards.

Flexibility and Scalability

AI technology in the food industry can be easily programmed and reprogrammed to handle various tasks, offering great flexibility. As demand changes, the same robotic systems can scale operations up or down without the need for extensive reconfiguration. This adaptability allows businesses to respond quickly to market trends and seasonal demands, maintaining efficiency and competitiveness.

Enhanced Customer Experience

With AI in food manufacturing, businesses can offer more customized and consistent food products. Quick service, high-quality output, and the ability to meet specific customer preferences lead to a better customer experience. Furthermore, AI-driven insights into customer preferences can guide menu development and promotional strategies, creating a more personalized and satisfying dining experience. Advanced predictive analytics allow for better inventory management, reducing waste and ensuring fresh ingredients. Additionally, AI-driven quality control systems enhance food safety standards, minimizing the risk of contamination and ensuring consumer trust.

Data-Driven Decision Making

AI systems can collect and analyze data on production processes, consumer preferences, and equipment performance. This data-driven approach helps businesses make informed decisions, optimize operations, and innovate in product development.

Leveraging real-time analytics, AI can pinpoint inefficiencies and highlight areas for enhancement, fostering a culture of continuous improvement. Additionally, predictive analytics can forecast market trends and consumer behavior, providing a competitive edge and facilitating proactive strategies. This comprehensive utilization of data transforms raw information into actionable insights, ensuring sustainable growth and operational excellence.

Waste Reduction and Sustainability

Integrating AI into food robotics can revolutionize sustainable practices by significantly enhancing resource optimization, waste reduction, and energy efficiency. This integration not only helps in achieving stringent environmental objectives but also bolsters the company’s reputation for sustainability.

Advanced AI algorithms can precisely forecast demand, thereby minimizing overproduction and subsequent food waste. Moreover, these algorithms support sustainable sourcing practices by ensuring efficient use of resources throughout the supply chain.

Enhanced predictive analytics enable more accurate inventory management, reducing the carbon footprint associated with excess storage and transportation. Furthermore, AI-driven energy management systems can optimize energy consumption, making operations more eco-friendly.

As evident, implementing AI in food robotics automation offers numerous benefits, from improving efficiency and consistency to enhancing safety and sustainability.

These advantages position businesses to meet the demands of modern consumers while maintaining high standards of quality and operational excellence.

Real World Examples of Businesses Using AI in the Food Industry

A number of food companies are using AI and machine learning for distinct purposes. Here are some of the notable AI in food industry examples:

Coca-Cola

Coca-Cola uses AI and ML algorithms to streamline its distribution and supply chain. The technology aids in precisely forecasting demand, ensuring that goods are accessible when and where needed, and reducing stockouts and surplus inventory.

Starbucks

Starbucks uses AI-driven personalization to provide customers with tailored recommendations in its mobile app. The app analyzes past orders, preferences, and location information to make appropriate personalized food and drink recommendations for each user.

Beyond Meat

To continually enhance the flavor and texture of its meat alternatives, this plant-based food company uses AI and ML. The technology examines sensory data, user feedback, and ingredient profiles to improve the flavor and consistency of the products.

Nestlé

Nestlé employs AI to develop and improve its products. AI-powered platforms examine market data, social media trends, and customer input to identify new food trends and create goods that appeal to the needs of the market.

These AI use cases in the food industry highlight how artificial intelligence (AI) and machine learning (ML) revolutionize the food sector by fostering creativity, efficiency, and customer-centric approaches to food production, supply chain management, and consumer experience.

Revolutionizing the Food Industry: The Future of AI and Robotics

The future of the food industry is poised for remarkable transformation, driven by the relentless advancement of artificial intelligence and robotics. Advanced algorithms will predict consumer demand with unprecedented accuracy, allowing for better inventory management and reducing food waste.

Autonomous vehicles and drones will revolutionize logistics, ensuring faster and more efficient deliveries. Moreover, AI and robotics will facilitate the development of new food products tailored to consumer preferences and health needs. Personalized nutrition, based on individual dietary requirements and genetic makeup, will become more accessible, promoting healthier lifestyles.

Sustainability will be a key focus. AI will help create circular food systems where waste is minimized, and resources are reused. Robotics will assist in recycling and managing food waste more effectively.

In the food industry, several advanced AI technologies are being utilized and are poised to play an even more significant role in the future. Here are some of the most important AI technologies transforming the food industry:

Computer Vision

Computer vision is revolutionizing quality control and sorting processes in the food industry. Automated inspection ensures that food products meet stringent quality standards by detecting defects and inconsistencies. This technology is particularly effective in sorting and grading produce based on various attributes such as size, color, and ripeness, which enhances efficiency and reduces manual labor.

Drones

Drones are becoming indispensable in modern agriculture, offering real-time aerial surveillance to assess crop health, identify pests, and monitor irrigation systems. With the integration of artificial intelligence applications in food production, these drones enable precision agriculture by allowing targeted application of fertilizers and pesticides, minimizing waste, and maximizing yield. This technological advancement is revolutionizing the agricultural sector, making farming more efficient and sustainable.

Robotic Automation

Robotic automation transforms food processing and harvesting, driving efficiency and reducing labor costs. In processing plants, robots handle and package food products precisely, increasing throughput and maintaining hygiene standards. Harvesting robots, equipped with advanced sensors and AI, can pick fruits and vegetables with minimal damage, ensuring high-quality produce.

Predictive Analytics

Predictive analytics leverages historical and real-time data to forecast future demand and optimize supply chain operations. By accurately predicting consumer demand, companies can maintain optimal inventory levels, reducing both overstock and stockouts. This technology also enhances supply chain efficiency by anticipating potential disruptions and adjusting logistics accordingly.

Natural Language Processing (NLP)

Natural Language Processing (NLP) enhances customer interactions and personalized experiences in the food industry. Through chatbots and virtual assistants, NLP provides instant, personalized recommendations and handles customer inquiries efficiently. It also powers AI-driven platforms that generate new recipes based on user preferences and dietary restrictions, offering a tailored culinary experience.

IoT and Smart Sensors

IoT and smart sensors are integral to advancing smart farming and cold chain monitoring in the food industry. These devices monitor soil moisture, temperature, and nutrient levels in real-time, enabling precise and efficient farming practices. In the cold chain, smart sensors ensure that perishable goods are stored and transported under optimal conditions, preventing spoilage and ensuring food safety.

Machine Learning

Machine learning is crucial for yield prediction and personalized nutrition in the food industry. By analyzing environmental and historical data, machine learning models can predict crop yields and optimize planting schedules, enhancing agricultural productivity. Additionally, this technology enables the development of personalized diet plans based on individual health data and preferences, promoting healthier eating habits.

Augmented Reality (AR) and Virtual Reality (VR)

AR and VR technologies provide immersive training experiences and enhance online shopping in the food industry. These technologies offer realistic simulations for training food industry workers, improving skills and safety. In virtual grocery shopping, AR and VR create interactive product displays and provide detailed nutritional information, offering a richer and more engaging shopping experience.

Blockchain

Blockchain technology ensures transparency and traceability in the food supply chain, from farm to table. Blockchain enhances food safety and authenticity by recording every transaction and movement of food products on a secure, immutable ledger. Smart contracts automate transactions and agreements, reducing fraud and improving efficiency.

Overcoming Challenges and Implementing Solutions for AI and Robotics in Food Automation

Let’s explore the challenges and solutions in AI and robotics for food automation. Addressing issues like precision, safety, and scalability, we’ll see how innovative technologies are transforming the food industry for enhanced efficiency and quality. From advanced sensors to intelligent algorithms, discover how to overcome obstacles and implement cutting-edge solutions in food automation.

Integration with Existing Systems

Challenge: Integrating new AI and robotic systems with existing production lines and IT infrastructure can be complex and time-consuming. Compatibility issues and potential disruptions to ongoing operations pose significant challenges.

Solution: Conduct thorough assessments of current systems and workflows. Employ middleware and integration platforms that facilitate seamless communication between old and new systems. Engage with experienced system integrators.

Workforce Resistance to Change

Challenge: Employees may resist the adoption of AI and robotics due to fears of job loss or the complexity of new technologies. This resistance can hinder the smooth implementation and utilization of these advanced systems.

Solution: Offer comprehensive training programs to upskill employees, highlighting the benefits of AI in food manufacturing and other areas. Foster a culture of innovation by involving staff in the implementation process and addressing their concerns.

Ensuring Food Safety and Quality

Challenge: Maintaining high standards of food safety and quality is critical, and the introduction of AI and robotics can introduce new variables that need to be tightly controlled. Ensuring consistent and reliable performance of these systems is essential.

Solution: Utilize advanced AI algorithms and sensors for real-time monitoring and quality control. Implement robust traceability systems that track products from farm to fork, ensuring compliance with food safety standards.

Data Privacy and Security

Challenge: One of the major challenges of AI in the food industry is data privacy. The increased use of AI and robotics involves the collection and processing of large amounts of data, raising concerns about data privacy and security. Protecting sensitive information from cyber threats is crucial.

Solution: Develop and enforce strict data governance policies to manage the vast amounts of data generated by artificial intelligence in the food industry. Invest in state-of-the-art cybersecurity measures to protect sensitive information, including encryption and secure access controls. This approach ensures that AI systems operate securely and effectively, safeguarding against potential breaches and maintaining the integrity of the data used in production processes.

Maintenance and Downtime

Challenge: AI and robotic systems require regular maintenance to function optimally. Unexpected breakdowns or downtime can disrupt production schedules and lead to significant financial losses.

Solution: Establish proactive maintenance schedules and invest in predictive maintenance technologies. Train in-house teams or partner with reliable service providers to ensure minimal downtime.

Customization and Flexibility

Challenge: The food industry demands high levels of customization and flexibility in production processes. Adapting artificial intelligence in the food industry and robotic systems to meet these needs can be challenging, especially when dealing with diverse products. Integrating AI solutions requires addressing various factors such as scalability, product variety, and real-time adjustments to maintain efficiency and quality.

Solution: Opt for modular and scalable robotic systems that can be easily customized and upgraded. Utilize artificial intelligence in the food industry to enable adaptive learning and responsiveness to changing production needs.

Regulatory Compliance

Challenge: Navigating the complex regulatory landscape in the food industry can be daunting. Ensuring that artificial intelligence in the food industry comply with all relevant regulations and standards is essential for legal and operational success.

Solution: Stay informed about the latest regulations and standards in the food industry. Engage with regulatory experts to ensure compliance throughout the implementation process and incorporate compliance checks into automated systems.

Scalability Issues

Challenge: Scaling AI and robotic solutions across multiple production lines or facilities can be difficult. Ensuring consistent performance and integration at a larger scale requires careful planning and execution.

Solution: Start with pilot projects to validate technology effectiveness and scalability. Develop a clear roadmap for scaling operations, incorporating lessons learned from initial implementations.

Technological Obsolescence

Challenge: Rapid advancements in AI and robotics technology can render current systems obsolete quickly. Keeping up with technological changes and ensuring ongoing relevance can be challenging.

Solution: Invest in upgradeable systems and maintain relationships with technology providers for continuous updates. Stay abreast of technological advancements and plan for regular equipment and software reviews and updates.

By addressing these challenges with targeted solutions, the food industry can effectively harness the power of AI and robotics to enhance productivity, ensure quality, and drive innovation.

Unlock Opportunities in Your Food Business with Appinventiv’s Intelligent AI Services

At Appinventiv, our software development team understands data’s crucial role in AI and ML. That’s why we offer scalable AI development services aimed at helping your company extract valuable insights from the vast amounts of structured and unstructured data it generates in various formats.

Appinventiv partners with businesses to create cutting-edge AI-driven solutions that seamlessly integrate into their operations. By focusing on each client’s unique needs and objectives, we develop high-quality applications that drive innovation and efficiency.

Our approach encompasses every stage of development, from initial concept and strategic UI/UX design to frontend and backend development, rigorous quality assurance, deployment, and ongoing maintenance. Through our dedication and expertise, Appinventiv consistently delivers exceptional AI solutions, earning a reputation as a leading name in the industry.

In our 9+ years of journey, we have empowered countless businesses to seize new opportunities and overcome operational challenges. Our portfolio includes global leaders like Domino’s, KFC, and Pizza Hut. This extensive client base solidifies our position as a trusted tech partner for businesses seeking cutting-edge software solutions.

Discover the possibilities of AI in the food industry with our advanced generative AI consulting solutions. Using our expertise, you can effectively identify and utilize crucial data, empowering you to make informed business decisions. Contact our IT experts to learn more about our AI development services and how they can benefit your organization.

FAQs

Q. What role does AI play in revolutionizing the food industry?

A. AI in the food industry utilizes technologies like data analytics and machine learning to enhance food production, precision agriculture, quality control, personalized nutrition, supply chain management, and customer experience. This leads to improved sustainability, efficiency, and innovation in the food ecosystem. The integration of artificial intelligence in food industry processes ensures smarter decision-making and optimized operations, driving progress and competitive advantage.

Q. How is robotics used in the food industry?

A. Robotics involves the development, manufacturing, and use of robots to automate various tasks. In the food industry, robotics enhances efficiency, safety, and consistency across multiple stages of production.

Robots handle tasks such as sorting, cutting, and portioning food items, improving product quality and reducing waste. Advanced vision systems enable robots to sort products by size, shape, and ripeness, while precision cutting robots maintain uniformity.

Q. What are the benefits of AI in the food service industry?

A. AI in the food service industry offers numerous benefits, including enhanced customer service through chatbots and virtual assistants for efficient order handling and personalized recommendations. It improves inventory management by predicting demand accurately, reducing waste, and ensuring optimal stock levels.

AI-driven automation in food preparation and delivery streamlines processes and increases efficiency. Additionally, AI enables personalized marketing strategies to boost sales and customer loyalty and enhances food safety by monitoring data to detect potential hazards and ensure compliance with safety standards.

How Much Does it Cost to Build a Custom AI-based Accounting Software?

The accounting industry has been evolving very fast, and the expanding use of AI in accounting is becoming evident. According to The State of AI in Accounting Report 2024, 71% of accounting professionals believe that artificial intelligence in accounting is substantial. Considering the given number, it is easy to grasp why companies are keen on…

Generative AI in Manufacturing: 10 Popular Use-Cases

Introduction Manufacturing is truly getting a serious makeover for the future, and it's not full of buzzwords and techno-speak; with the dawning of AI technologies, manufacturing is no longer about nuts and bolts and conveyor belts. Yes! We are talking about how Generative AI in manufacturing is transforming the entire industry. It was the next…